Fujitsu Achieves High-Volume Data Conversion of Over 2GB With Launch of iCAD SX V7L5

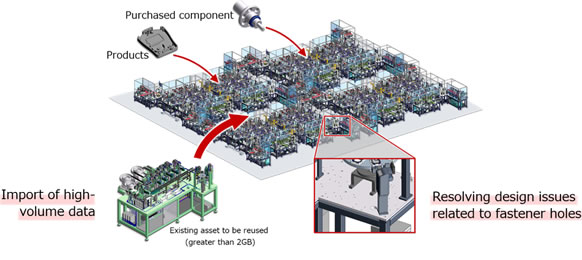

This product features an enhanced ability to convert data created in other 3D CAD programs into iCAD SX data, with the ability to process the conversion of high-volume data of over 2GB, roughly ten times that of previous versions. This makes it possible to batch import 3D models, such as data for purchased components, designs from other companies, or previously purchased devices or units, enabling users to quickly carry out design studies of large-scale installations as a whole.

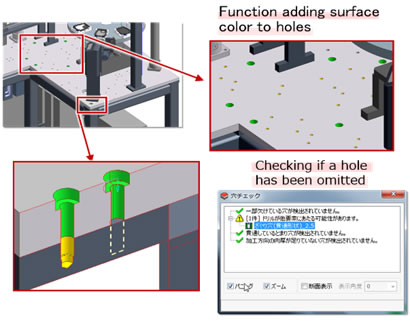

Moreover, in regard to the fastener holes necessary for the over ten-thousand screw clamps that can exist in machines and equipment, Fujitsu has added a function to instantly determine design points of failure, such as the wrong type of hole, pierced-through blind holes, or an omission of a hole, and warn the user, enabling standardization of verification work, which was previously up to an individual's judgement. Furthermore, Fujitsu has improved the ability to search through text information, such as correction requests input to the 3D CAD by the production department, allowing designers to instantly search for points of failure in the huge plan.

Through these features, not only can users reduce the number of hours required to import high-volume data and the effort necessary to determine and correct points of failure, they can also further improve the quality of their designs.

The iCAD SX software can design in 3D such things as large-scale production facilities or machine tools, with tens of thousands of components, and process them at high speeds. In the machinery and equipment industry, the need for rapid product output in the face of increasingly severe global competition and for the ability to develop increasingly complex products are important issues. For this reason, there is a demand for even greater reductions in design man-hours and improvements in design quality among machinery and equipment makers.

In order to resolve these types of issues, Fujitsu has provided not only the ability to convert and process large volumes of data on a scale of over 2GB, which could not previously be imported at once, but also the ability to check design points of failure, and conduct searches.

Figure 1: Image of iCAD SX V7L5

Figure 1: Image of iCAD SX V7L5

Features of iCAD SX V7L5

1. Improved performance when processing conversion of high-volume data

By greatly reducing the amount of memory used when converting data, this product can convert approximately 10 times the volume of data it could previously. This enables the software to batch import 3D CAD files created in other programs for products, surrounding equipment, purchased components, existing units and so forth, and quickly create large-scale equipment data, including the imported data.

2. Improved ability to check fastener holes, the cause of the majority of design defects

With most machinery and equipment, there are ten-thousand plus fastener holes, and a major cause of design failures is the incorrect sizing, type, or placement of these holes. This product features automatic detection and a warning for the user when among the holes in large-scale equipment there is a wrong type of hole, when holes intended to be blind are pierced through, or when there has been a failure to make a hole. Furthermore, it makes it easy to repeatedly check and correct problems during design, with a surface color function that adds a different color to different types of holes, as well as a function for changing hole position. This makes it possible to standardize the judgement criteria in verification tasks, rather than leaving it to individual judgement, thereby improving design quality.

Figure 2: Fastener hole verification functions

Figure 2: Fastener hole verification functions

3. Improved ability to search feedback from manufacturing departments

Designers spend a lot of time searching for points of failure across huge 3D CAD plans, in response to correction requests from the production department. With this product, designers can instantaneously find the points of failure pointed out by the production department by searching through the text data directions they have input into the 3D CAD model. This makes it possible to rapidly reflect the correction requests from the production department, reducing the man-hours required to correct the plan.

Pricing and Availability

| Product Name | Retail Price (excl. tax) | Availability Date |

|---|---|---|

| FUJITSU Manufacturing Industry Solution iCAD SX V7L5 (CAD for machinery design) | Starting at JPY 1.38 million | February 12, 2016 |

Sales Target

13,000 packages in fiscal 2016 (Fujitsu's fiscal year ends at the end of March).

All company or product names mentioned herein are trademarks or registered trademarks of their respective owners. Information provided in this press release is accurate at time of publication and is subject to change without advance notice.

Комментарии