Fujitsu's Flexible, Battery-less Beacon Is First in World to Obtain ucode Tag Certification

This beacon prototype will be exhibited at the 2015 TRON Symposium -TRONSHOW-, to be held from December 9 through December 11, 2015, at Tokyo Midtown.

Issues with Conventional Beacons

Conventional beacons require either a built-in battery, which must be changed regularly, or a nearby outlet to continually provide the power necessary to transmit signals, requiring a great deal of effort for operations management, such as regular maintenance or extensive installation work. Furthermore, as most beacons have a hard cover such as plastic, there are issues with deployment to locations where it is necessary to blend into the scenery or with the danger of a beacon falling.

Moreover, because ordinary beacons transmit IDs that were each independently systematized within a variety of industries and organizations, there is a possibility of ID duplication, limiting their use to within each independent system.

Features of the Prototype

1. Improved potential for mass-production with a simple circuit layout and a redesigned manufacturing process

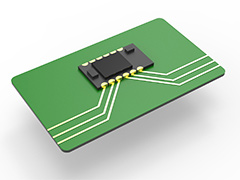

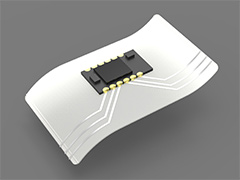

With the recently developed beacon(4), a conductive paste is printed on an electric circuit wiring pattern, to which electric components are mounted and connected with conductive adhesive. The paste and adhesive materials were selected to enable mass-production with existing production facilities.

With the beacons currently under development, the circuit design was refined to enable mass-production with more general electric components. In addition, the drying process for the paste and connections between electric components has been thoroughly optimized for time and temperature, with the aim of more efficient production. This will shorten the previous manufacturing time, also enabling cost reductions.

2. Realizes new location information services by broadcasting a unique ID

This is the world's first certification of a beacon for ucode Category 2(5) of ucode tags from TRON Forum, an organization dedicated to the standardization and promotion of core technologies for ubiquitous computing. By receiving this certification, the beacon is now capable of using IDs compliant with international standards, making possible safer, more secure, and highly reliable location information services, such as guidance support for the visually impaired within stations or around town, or efficient seat management for stadiums. Furthermore, beacons were previously installed only on fixed structures such as buildings, but because the new prototype features the ability to change shape, it can also be affixed to clothes and shoes, making it easier to attach to people or mobile platforms. It then becomes possible to easily grasp the location of such people and things to provide them with support.

| Ordinary Beacons | Prototype | |

|---|---|---|

| Printed Circuit Board |  |

|

| Base Substrate | Hard substrates such as glass epoxy | A soft silicone sheet |

| Wiring | Copper layer deposited with chemical processing | Printed conductive paste |

| Electric Component Mounting | Attached with solder | Attached with a conductive adhesive |

Future Developments

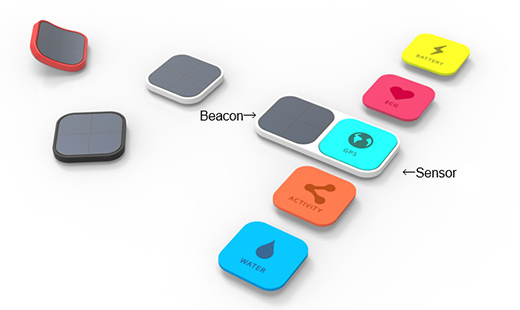

Going forward, Fujitsu is aiming to establish a manufacturing process with even greater production efficiency, leading to early commercialization. In addition, they plan to create new location information solutions combining this beacon with sensing technologies.

Figure: Potential future product (using the beacon in combination with sensors such as heart-rate sensors and accelerometers)

Figure: Potential future product (using the beacon in combination with sensors such as heart-rate sensors and accelerometers)

Remarks from University of Tokyo Professor Ken Sakamura

(Chair of the TRON Forum, Director of the YRP Ubiquitous Networking Laboratory)

"Fujitsu has now developed a beacon that has been certified as a ucode tag. In the world of IoT, it is necessary to identify individual things and locations, and a beacon is an effective device for that purpose. However, conventional beacons can be difficult to install and maintain, so I had been expecting that R&D conducted by industry would come up with a solution. Now this beacon has the potential to do just that, and together with moving a step closer to the realization of an IoT world, I feel it demonstrates the fundamental strengths of Japanese technology. I'm looking forward to this beacon being put to actual use, and to its spread around the world."

Related Website

All company or product names mentioned herein are trademarks or registered trademarks of their respective owners. Information provided in this press release is accurate at time of publication and is subject to change without advance notice.

Комментарии